1. Artificial Intelligence (AI) and machine learning

The utilization of Artificial Intelligence (AI) and machine learning in robotics and automation continues to expand as a prominent trend. With the advent of generative AI, new avenues for innovation are being explored. This specialized subset of AI is adept at generating novel solutions based on acquired knowledge, a concept popularized by tools like ChatGPT. Robot manufacturers are pioneering generative AI-driven interfaces, enabling users to intuitively program robots using natural language instead of complex code. This advancement eliminates the necessity for specialized programming skills among workers, as they can now easily select and adjust robot actions.

Furthermore, predictive AI is revolutionizing the landscape by analyzing performance data of robots to anticipate future equipment states. Predictive maintenance, facilitated by this technology, holds immense potential for cost savings in manufacturing industries. For instance, the Information Technology & Innovation Foundation reports that in the automotive parts sector, each hour of unplanned downtime incurs an estimated cost of US$1.3 million. This underscores the significant cost-saving opportunities presented by predictive maintenance strategies. Additionally, machine learning algorithms can analyze data from multiple robots engaged in similar processes to optimize efficiency. It’s widely acknowledged that machine learning algorithms improve in performance as they’re provided with more data, underscoring the importance of data-driven optimization in automation.

2. Cobots expanding to new applications

The trend of human-robot collaboration continues to gain momentum in the field of robotics, with collaborative robots, or cobots, expanding into new applications. This evolution is propelled by rapid advancements in sensors, vision technologies, and smart grippers, enabling robots to dynamically respond to changes in their environment and operate safely alongside human workers.

Cobots are increasingly becoming invaluable tools for human workers, providing support and assistance in various tasks. They excel in activities involving heavy lifting, repetitive motions, or hazardous environments, thereby enhancing worker safety and productivity.

The array of collaborative applications offered by robot manufacturers is continuously broadening, reflecting the growing versatility and capabilities of cobots. One notable market trend is the rising adoption of cobot welding applications, driven by a shortage of skilled welders. This trend underscores the notion that automation doesn’t lead to labor scarcity but rather offers a solution to it. Collaborative robots serve to complement traditional industrial robots, which operate at higher speeds and play a crucial role in enhancing productivity amidst tight product margins.

Moreover, new entrants are entering the market with a specific focus on cobots, further diversifying the landscape. Mobile manipulators, which combine collaborative robot arms with mobile robots (AMRs), present novel use cases that could significantly expand the demand for collaborative robots.

In essence, the expansion of cobots into new applications signifies a paradigm shift in the way humans and robots collaborate in various industries. With continued innovation and integration, cobots are poised to play an increasingly vital role in enhancing efficiency, safety, and productivity across diverse sectors.

3. Mobile manipulators

In various industries such as automotive, logistics, and aerospace, a revolutionary automation solution known as Mobile Manipulators, often referred to as “MoMas,” is transforming material handling tasks. These innovative robots combine the mobility of robotic platforms with the dexterity of manipulator arms, enabling them to navigate intricate environments and manipulate objects with precision. This versatility is particularly crucial for applications in manufacturing settings.

Equipped with advanced sensors and cameras, mobile manipulators excel in performing inspections and executing maintenance tasks on machinery and equipment. Their ability to navigate dynamic environments and interact with diverse objects makes them indispensable assets in modern manufacturing operations.

One of the most significant advantages of mobile manipulators is their capacity to collaborate with and support human workers. As the industry grapples with a shortage of skilled labor and struggles to attract staff to factory jobs, the demand for automation solutions like mobile manipulators is expected to rise steadily. These robots not only streamline operations but also augment the capabilities of human workers, enhancing overall productivity and efficiency.

In summary, mobile manipulators represent a groundbreaking advancement in automation technology, offering unparalleled flexibility, adaptability, and collaborative potential. As industries continue to embrace automation to address labor shortages and improve operational efficiency, mobile manipulators are poised to play a pivotal role in shaping the future of manufacturing and material handling.

4. Digital twins

Digital twin technology is gaining traction as a powerful tool for optimizing the performance of physical systems by generating virtual replicas. With the growing integration of robots in factory settings, digital twins leverage real-world operational data from these robots to conduct simulations and forecast potential outcomes. Unlike their physical counterparts, digital twins exist solely as computer models, allowing for stress-testing and modifications without any safety concerns, thus saving costs. Through digital twins, all experimentation can be thoroughly vetted before any actions are executed in the physical realm. Essentially, digital twins serve as a bridge between the digital and physical worlds, facilitating enhanced efficiency and informed decision-making in various industrial applications.

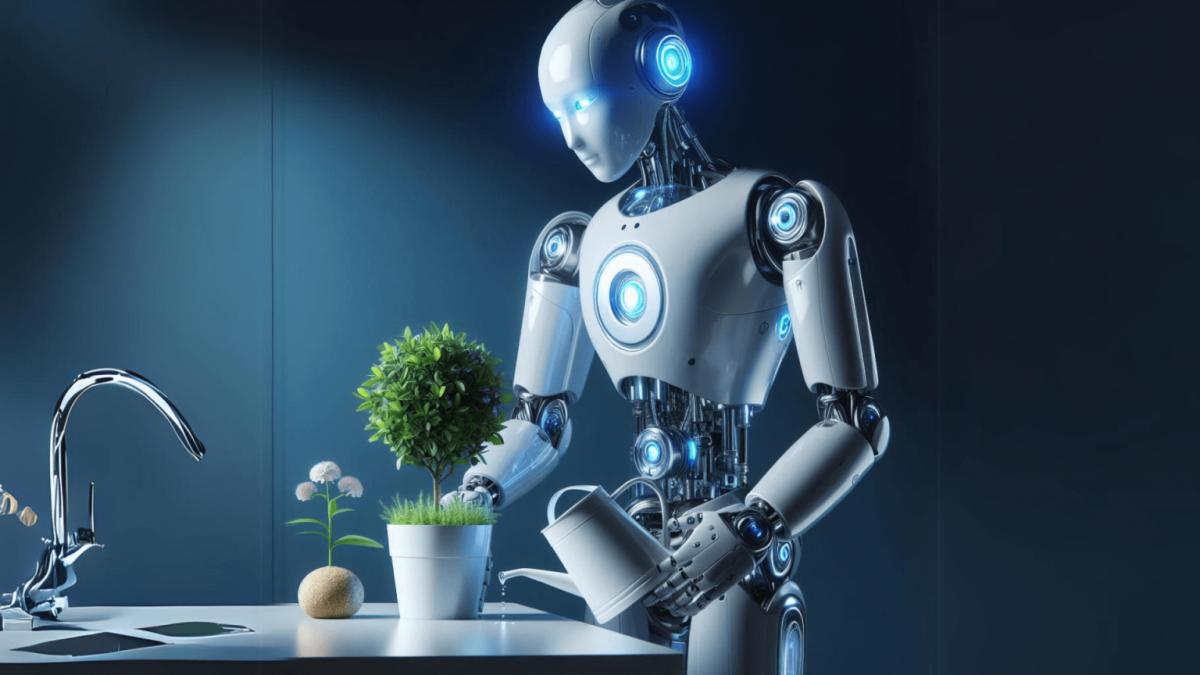

5. Humanoid Robots

Humanoid robots represent a notable breakthrough in robotics, showcasing remarkable capabilities to undertake diverse tasks across various environments. With their human-like design featuring two arms and two legs, these robots boast adaptability in work settings originally tailored for humans. This flexibility enables seamless integration into existing warehouse processes and infrastructure, facilitating efficient utilization across a spectrum of applications.

The Chinese Ministry of Industry and Information Technology (MIIT) has recently unveiled detailed objectives aimed at achieving mass production of humanoid robots by 2025. According to MIIT, humanoids are poised to emerge as a disruptive technology akin to computers or smartphones, potentially revolutionizing manufacturing processes and redefining human lifestyles.

The prospect of humanoids exerting influence across various sectors renders them a captivating area of development. However, the widespread adoption of humanoid robots presents a multifaceted challenge. Cost considerations stand out as a pivotal factor, with the success of humanoids contingent upon their ability to deliver a competitive return on investment vis-à-vis established robotic solutions such as mobile manipulators.

Marina Bill, President of the International Federation of Robotics, emphasizes the significance of these developments, stating, “The five mutually reinforcing automation trends in 2024 underscore robotics as a multidisciplinary field where technologies converge to create intelligent solutions for diverse tasks. These advancements continue to shape the convergence of industrial and service robotics sectors, as well as the future of work.”